Engineering, 08.02.2022 02:30 ogbobbythman6154

Part 2.

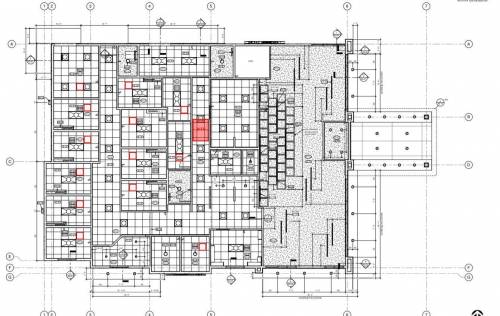

Your task is to design (i. e., layout and size) supply ductwork for a portion of a medical office building. Using the drawing provided, which shows locations of supply diffusers, return grills, and the RTU (which serves as the AHU), show where the ductwork will be laid out, and indicate the size of circular duct for all portions of the ductwork. The supply diffusers are shown as red boxes and the RTU is labeled as such.

To determine CFM per diffuser, use the “1 square foot = 1 CFM” rule-of-thumb. (Hint: The ceiling tiles shown on the plan are each 2’ x 2’.)

Assume all ducts will be circular.

Assume friction loss of 0.1.

You may use a duct calculator from class, borrow one from my office (Owen 250), or use an online calculator. Please return them to me in class or at Owen 250 when you are finished.

Your submittal must be easy to read and professional in appearance, and the duct sizes must be reasonably accurate.

Here's some guidance on how to do Part 2 on duct sizing.

Duct sizing:

• Start with the supply ductwork. The supply diffusers are the red boxes on the drawing. Determine the cfm of air from each diffuser from the square footage of the room (1 sf = 1 cfm). Ceiling tiles are 2 ft x 2 ft on the "reflected ceiling plan" drawing provided.

• The duct supplying a diffuser must also carry that cfm. Use a duct calculator to find duct size...https://www. oceanhvac. com/ductulator/

• Use 0.1 / 100 ft for friction and keep other default values. Enter the cfm for that duct and click "Calculate" to find the round duct size.

• Work your way upstream towards the RTU, joining ductwork to other ductwork from other diffusers. When two ducts join, the combined duct must be recalculated using the combined cfm. Ductwork is larger farther upstream.

• Repeat the process for return ductwork, with one return grill per room (you must place the grill yourself).

• Try to find the most efficient path the get both supply and return ductwork back to the RTU!

Answers: 1

Another question on Engineering

Engineering, 03.07.2019 14:10

The y form of iron is known as: a) ferrite b) cementite c) perlite d) austenite

Answers: 3

Engineering, 04.07.2019 18:20

Derive the correction factor formula for conical nozzle i=-(1+ cosa) and calculate the nozzle angle correction factor for a nozzle whose divergence hal-fangle is 13 (hint: assume that all the mass flow originates at the apex of the cone.

Answers: 3

Engineering, 04.07.2019 18:20

Asolid cylinder is concentric with a straight pipe. the cylinder is 0.5 m long and has an outside diameter of 8 cm. the pipe has an inside diameter of 8.5 cm. the annulus between the cylinder ad the pipe contains stationary oil. the oil has a specific gravity of 0.92 and a kinematic viscosity of 5.57 x 10-4 m2/s. most nearly, what is the force needed to move the cylinder along the pipe at a constant velocity of 1 m/s?

Answers: 3

Engineering, 04.07.2019 18:20

Amixture of slurry and mud is to be pumped through a horizontal pipe of diameter 500 mm. the fluid behaves as a bingham plastic with a yield stress of 30 pa and viscosity 0.04 pa.s. describe the effects of the shear stress through a transverse section of the pipe by plotting the variation in shear stress and velocity profile: (i) just before the slurry starts to move (ii) as the slurry flows when the pressure gradient is double that in part (i)

Answers: 3

You know the right answer?

Part 2.

Your task is to design (i. e., layout and size) supply ductwork for a portion of a medical...

Questions

Mathematics, 12.08.2020 05:01

Computers and Technology, 12.08.2020 05:01

Computers and Technology, 12.08.2020 05:01

Mathematics, 12.08.2020 05:01

Spanish, 12.08.2020 05:01

Chemistry, 12.08.2020 05:01

History, 12.08.2020 05:01