Engineering, 08.09.2021 19:10 QUEEN2267

Assignment Summary

For this assignment, you will apply what you know about the technological design process to solve an Earth Science–related problem in your community.

Background Information

Engineers and scientists are problem solvers. They design and make products that help solve problems such as pollution, erosion, and even climate change. The products they make help keep Earth healthy. For example, engineers have designed the equipment in water treatment plants to improve the quality of water used by homes and businesses. This equipment allows water to be reused and reintroduced into the water cycle without harming the environment or living things on Earth. The technological design process is useful in addressing large- and small-scale problems.

Materials

Varies by prototype/model Assignment Instructions

For this project, you are expected to submit the following:

1. Your Student Guide with completed Student Worksheet

2. Your prototype or model

Step 1: Prepare for the project.

a) Read through the guide before you begin so you know the expectations for this project.

b) If anything is not clear to you, be sure to ask your teacher.

Step 2: Identify a problem or need in your community that can be solved by applying the

technological design process.

a) Choose a problem that is Earth Science–related, such as decreasing pollution, erosion, or damage due to natural disasters. Describe the problem in the appropriate space in the Student Worksheet.

b) Research related information that will tell you more about the problem or help you solve it.

i. Be sure to use reliable sources.

ii. Record your findings in the appropriate space in the Student Worksheet.

iii. List the sources you used at the end of the Student Worksheet.

Step 3: Design solutions to the problem.

a) Establish criteria that your solution should meet. List them from most important to least important

in the appropriate space in the Student Worksheet.

b) Draw prototypes/models of possible solutions in the appropriate space in the

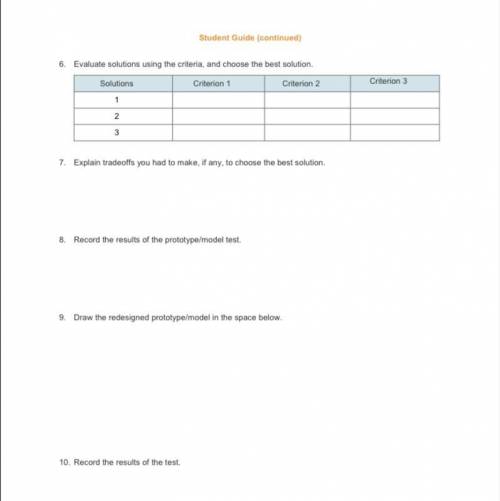

c) Evaluate the possible solutions against the criteria. Use the table in the Student Worksheet to evaluate the possible solutions. Add more columns and rows if necessary.

d) Choose the best solution. Highlight the best solution in the table in the Student Worksheet and explain the tradeoffs you had to make, if any.

Step 4: Implement the solution.

a) Prepare the materials you need to build a prototype/model.

b) Build a prototype/model of the product.

c) Test the prototype/model.

d) Analyze the results of your test. Record your findings in the appropriate space in the Student Worksheet.

e) If your test shows that your product/model is successful, submit your prototype/model to your teacher. Be sure to put your name on it. Then, proceed to step 6. If your test is not successful, continue to step 5.

Step 5: Redesign and retest solution (if necessary).

a) Adjust the design of your prototype as necessary. Draw your redesigned prototype/model in the

space provided in the Student Worksheet.

b) Retest the prototype/model.

c) Analyze the results of your test. Record your findings in the appropriate space in the Student Worksheet.

d) Submit your prototype/model to your teacher. Be sure to put your name on it.

Step 6: Evaluate your project using this checklist.

If you can check each box below, you are ready to submit your project.

Did you identify an Earth Science–related problem in your community?

Did you do related research to help you solve the problem?

Did you list your sources at the end of the Student Worksheet?

Did you establish criteria for your solution? Did you list the criteria in order from most important to

least important?

Did you draw prototypes/models of possible solutions?

Did you evaluate possible solutions against the criteria?

Did you choose the best solution? Did you highlight the best solution in the table?

Did you explain tradeoffs you had to make, if any?

Did you create a prototype/model of the best solution?

Did you test your prototype/model? Did you record the results of your test?

Did you redesign your prototype/model if the original prototype/model did not work the way it was

supposed to?

Did you test your new prototype/model? Did you record the results of your test?

Did you complete your Student Worksheet and submit it online?

Student Guide (continued)

Did you submit your prototype/model to your teacher? Step 7: Revise and submit your project.

a) If you were unable to check off all the requirements on the checklist, go back and make sure that your project is complete. Save your project before submitting it.

b) Turn in your prototype/model to your teacher.

c) Submit your Student Guide through the Virtual Classroom.

d) Congratulations! You have completed your project.

Student Guide (continued)

Answers: 3

Another question on Engineering

Engineering, 04.07.2019 18:10

Aplate clutch has a single pair of mating friction surfaces 250-mm od by 175-mm id. the mean value of the coefficient of friction is 0.30, and the actuating force is 4 kn. a) find the maximum pressure and the torque capacity using the uniform-wear model. b) find the maximum pressure and the torque capacity using the uniform-pressure model.

Answers: 3

Engineering, 04.07.2019 18:10

Condition monitoring is a major component of. (clo4) a)- predictive maintenance. b)-preventive maintenance c)-proactive maintenance d)-reactive maintenance.

Answers: 1

Engineering, 04.07.2019 18:10

Ifa component is made of two or more materials with different modulus of elasticity (e), it is called a composite member and we calculate the factor·n". mention the formula for calculating n". also, ifn> 1, explain what will happen to the 1. transformed.gi) ifn 1, what will happen to the material when transformed material when

Answers: 1

Engineering, 04.07.2019 18:10

Aturning operation is performed with following conditions: rake angle of 12°, a feed of 0.35 mm/rev, and a depth of cut of 1.1 mm. the work piece is aluminum alloy 6061 with t6 heat treatment (a16061-t6). the resultant chip thickness was measured to be 1.0 mm. estimate the cutting force, fc. use shear stress of 207 mpa and coefficient of friction on the tool face of 0.6.

Answers: 1

You know the right answer?

Assignment Summary

For this assignment, you will apply what you know about the technological desig...

Questions

Mathematics, 18.03.2021 17:40

Mathematics, 18.03.2021 17:40

Mathematics, 18.03.2021 17:40

History, 18.03.2021 17:40

History, 18.03.2021 17:40

Mathematics, 18.03.2021 17:40

Mathematics, 18.03.2021 17:40

Mathematics, 18.03.2021 17:40

Mathematics, 18.03.2021 17:40

Mathematics, 18.03.2021 17:40