Engineering, 03.06.2021 23:50 miriammayo12345

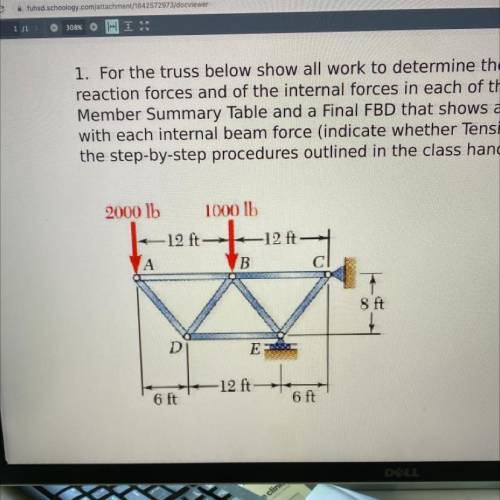

1. For the truss below show all work to determine the magnitude of external reaction forces and of the internal forces in each of the members. Include a Member Summary Table and a Final FBD that shows all the external forces along with each internal beam force (indicate whether Tension or Compression). Follow the step-by-step procedures outlined in the class handout. (100points)

Answers: 2

Another question on Engineering

Engineering, 04.07.2019 16:10

An electrical motor raises a 50kg load at a construct velencity .calculate the power of the motor, if it takes 40sec to raise the load through a height of 24m(take g =9.8n/g)

Answers: 2

Engineering, 04.07.2019 19:10

A)-explain briefly the importance of standards in engineering design. b)- what is patent? c)-explain the relationship between these standards: b.s. and b.s.en d)- in engineering design concepts, types of loads and how they act are important factors. explain.

Answers: 3

Engineering, 04.07.2019 19:20

Liquid flows at steady state at a rate of 2 lb/'s through a pump, which operates to raise the elevation of the liquid 100 ft from control volume inlet to exit. the liquid specific enthalpy at the inlet is 40.09 btu/lb and at the exit is 40.94 btub. the pump requires 3 btu/s of power to operate. if kinetic energy effects are negligible and gravitational acceleration is 32.174 tt/s, the heat transfer rate associated with this steady state process is most closely 1)-2,02 btu/s from the liquid to the surroundings 2)-3.98 btu/s from the surroundings to the liquid. 3)-4.96 btu/s from the surroundings to the liquid. 4)-1.04 btu/s from the liquid to the surroundings.

Answers: 2

Engineering, 04.07.2019 19:20

Ashielded metal arc-welding operation is accomplished in a work cell by a fitter and a welder. the fitter takes 5.5 min to load components into the welding fixture at the beginning of the work cycle, and 1.5 min to unload the completed weldment at the end of the cycle. the total ength of the weld seams 1200 mm, and the travel speed used by the welder averages 300 mm/min. every 600 mm of seam length, the welding stick must be changed, which takes 0.8 min. while the fitter is working, the welder is idle (resting): and while the welder is working the fitter is idle. (a) determine the average arc-on time as a fraction of the work cycle time. (b) how much improvement in arc-on time would result if the welder used flux-cored arc welding (manually operated), given that the spool of weld wire must be changed every 10 weldments, and it takes the welder 5.0 min to accomplish the change? (c) what are the production rates for these two cases (weldments completed per hour)? attach your work and solutions.

Answers: 1

You know the right answer?

1. For the truss below show all work to determine the magnitude of external reaction forces and of t...

Questions

Spanish, 10.12.2021 14:00

World Languages, 10.12.2021 14:00

Mathematics, 10.12.2021 14:00

English, 10.12.2021 14:00

English, 10.12.2021 14:00

English, 10.12.2021 14:00

English, 10.12.2021 14:00

Biology, 10.12.2021 14:00

English, 10.12.2021 14:00