Engineering, 20.10.2020 20:01 angelinaranee15

It is desired to enrich the partial pressure of hydrogen in a hydrogen–nitrogen gas mixture for which the partial pressures of both gases are 0.1013 MPa (1 atm). It has been proposed to accomplish this by passing both gases through a thin sheet of some metal at an elevated temperature; in as much as hydrogen diffuses through the plate at a higher rate than does nitrogen, the partial pressure of hydrogen will be higher on the exit side of the sheet. The design calls for partial pressures of 0.051 MPa (0.5 atm) and 0.01013 MPa (0.1 atm), respectively, for hydrogen and nitrogen. The concentrations of hydrogen and nitrogen (CHC

H and CNC N , in mol/m3mol/m

3 ) in this metal are functions of gas partial pressures (pH2 and pN2p

H 2 and p N , in MPa) and absolute temperature and are given by the following expressions:

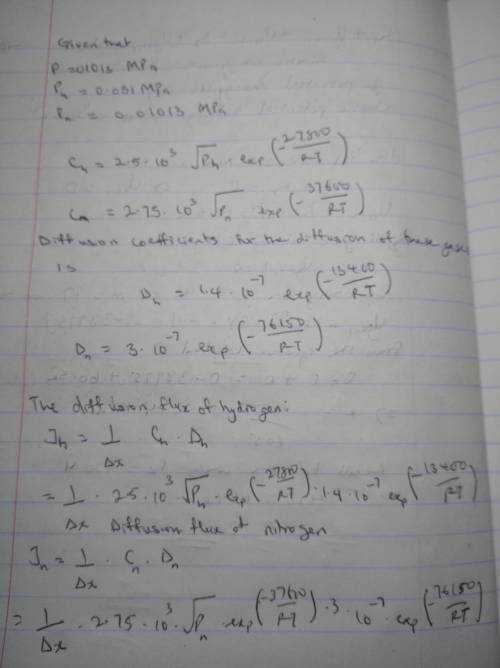

CH=2.5×103√pH2exp(−27,800J/mol/RT)

CN=2.75×103√pN2exp(−37,600J/mol/RT )

Furthermore, the diffusion coefficients for the diffusion of these gases in this metal are functions of the absolute temperature, as follows:

DH(m2/s)=1.4×10−7exp(−13,400J/mol/R T)

DN(m2/s)=3.0×10−7exp(−76,150J/mol/R T)

Is it possible to purify hydrogen gas in this manner? If so, specify a temperature at which the process may be carried out, and also the thickness of metal sheet that would be required. If this procedure is not possible, then state the reason(s) why.

Answers: 2

Another question on Engineering

Engineering, 03.07.2019 14:10

If the thermal strain developed in polyimide film during deposition is given as 0.0044. assume room temperature is kept at 17.3 c, and thermal coefficient of expansion for the film and the substrate are 54 x 10^-6c^-1 and 3.3 x 10^-6c^-1respectively. calculate the deposition temperature.

Answers: 3

Engineering, 04.07.2019 18:10

Manometers are good examples of measuring instruments, nowadays they are not as common as before. a)-capacitive probe gauges b)-gravitational gauges deformation ) gauges d)-digital gauges

Answers: 1

Engineering, 04.07.2019 18:10

Ifa component is made of two or more materials with different modulus of elasticity (e), it is called a composite member and we calculate the factor·n". mention the formula for calculating n". also, ifn> 1, explain what will happen to the 1. transformed.gi) ifn 1, what will happen to the material when transformed material when

Answers: 1

Engineering, 04.07.2019 18:10

Aturning operation is performed with following conditions: rake angle of 12°, a feed of 0.35 mm/rev, and a depth of cut of 1.1 mm. the work piece is aluminum alloy 6061 with t6 heat treatment (a16061-t6). the resultant chip thickness was measured to be 1.0 mm. estimate the cutting force, fc. use shear stress of 207 mpa and coefficient of friction on the tool face of 0.6.

Answers: 1

You know the right answer?

It is desired to enrich the partial pressure of hydrogen in a hydrogen–nitrogen gas mixture for whic...

Questions

Chemistry, 23.06.2019 03:30

Mathematics, 23.06.2019 03:30

Social Studies, 23.06.2019 03:30

Mathematics, 23.06.2019 03:30

Chemistry, 23.06.2019 03:30

Mathematics, 23.06.2019 03:30

English, 23.06.2019 03:30

Mathematics, 23.06.2019 03:30

Mathematics, 23.06.2019 03:30

Business, 23.06.2019 03:30

Mathematics, 23.06.2019 03:30