Engineering, 24.06.2020 06:01 ryliepeloquinf

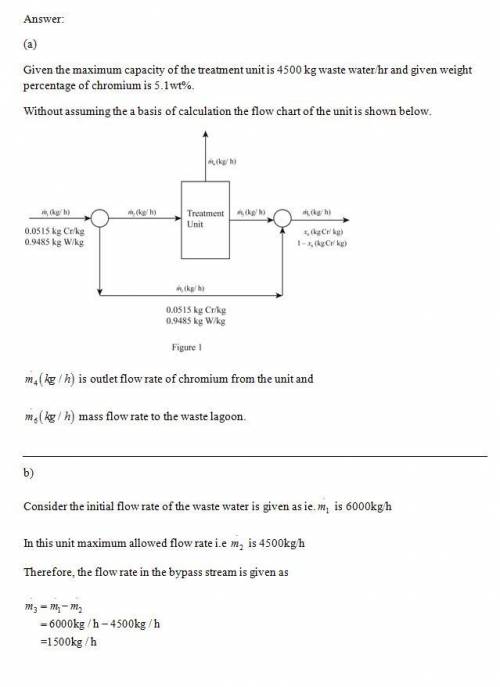

Effluents from metal-finishing plants have the potential of discharging undesirable quantities of metals, such as cadmium, nickel, lead, manganese, and chromium, in forms that are detrimental to water and air quality. A local metal-finishing plant has identified a wastewater stream that contains 5.15 wt% chromium (Cr) and devised the following approach to lowering risk and recovering the valuable metal. The wastewater stream is fed to a treatment unit that removes 95% of the chromium in the feed and recycles it to the plant. The residual liquid stream leaving the treatment unit is sent to a waste lagoon. The treatment unit has a maximum capacity of 4500 kg wastewater/h. If wastewater leaves the finishing plant at a rate higher than the capacity of the treatment unit, the excess (anything above 4500 kg/h) bypasses the unit and combines with the residual liquid leaving the unit, and the combined stream goes to the waste lagoon.

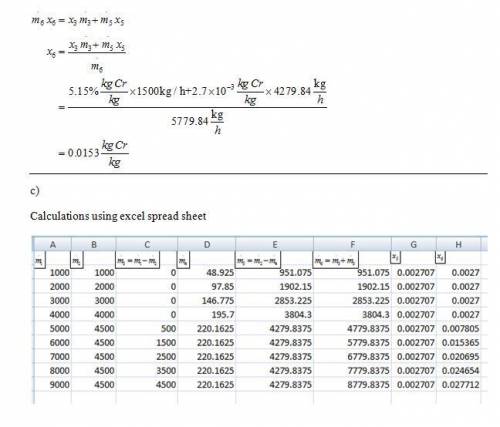

(a) Without assuming a basis of calculation, draw and label a flowchart of the process. (b) Waste water leaves the finishing plant at a rate m_ 1 ? 6000 kg/h. Calculate the flow rate of liquid to

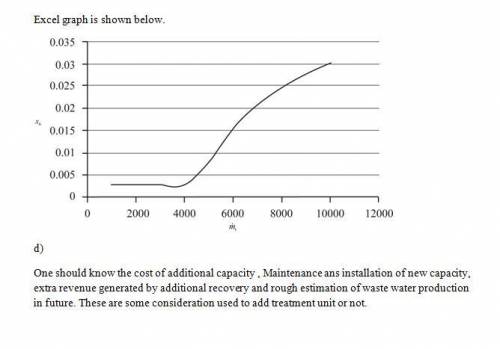

the waste lagoon, m_ 6?kg/h?, and the mass fraction of Cr in this liquid, x6(kg Cr/kg). (c) Calculate the flow rate of the liquid to the waste lagoon and the mass fraction of Cr in this liquid for m_1 varying from 1000 kg/h to 10,000 kg/h in 1000 kg/h increments. Generate a plot of x6 versus m_ 1 .

(Suggestion: Use a spreadsheet for these calculations.) (d) The company has hired you as a consultant to help them determine whether or not to add capacity to the treatment unit to increase the recovery of chromium. What would you need to know to make this determination? (e) What concerns might need to be addressed regarding the waste lagoon?

Answers: 3

Another question on Engineering

Engineering, 04.07.2019 18:10

An air conditioning system consist of a 5 cm diameter pipe, operating at a pressure of 200 kpa. the air initially enters the pipe at 15°c with a velocity of 20 m/s and relative humidity of 80%. if the heat supply throughout the process is 960 w, determine the relative humidity and the temperature at the outlet

Answers: 3

Engineering, 04.07.2019 18:10

For the closed feedwater heater below, feedwater enters state 3 at a pressure of 2000 psia and temperature of 420 °f at a rate of ix10 ibhr. the feedwat extracted steam enters state 1 at a pressure of 1000 psia and enthalpy of 1500 btu/lbm. the extracted er leaves at an enthalpy of 528.7 btu/lbm steam leaves as a saturated liquid. (16) a) determine the mass flow rate of the extraction steam used to heat the feedwater (10) b) determine the terminal temperature difference of the closed feedwater heater

Answers: 3

Engineering, 04.07.2019 18:10

Condition monitoring is a major component of. (clo4) a)- predictive maintenance. b)-preventive maintenance c)-proactive maintenance d)-reactive maintenance.

Answers: 1

Engineering, 04.07.2019 18:10

Atmospheric air has a temperature (dry bulb) of 80° f and a wet bulb temperature of 60° f when the barometric pressure is 14.696 psia. determine the specific humidity, grains/lb dry air. a. 11.4 c. 55.8 d. 22.5 b. 44.1

Answers: 1

You know the right answer?

Effluents from metal-finishing plants have the potential of discharging undesirable quantities of me...

Questions

Biology, 18.09.2019 03:40

Biology, 18.09.2019 03:40

Mathematics, 18.09.2019 03:40

Spanish, 18.09.2019 03:40

History, 18.09.2019 03:40

Spanish, 18.09.2019 03:40

Social Studies, 18.09.2019 03:40

History, 18.09.2019 03:40

Mathematics, 18.09.2019 03:40

Mathematics, 18.09.2019 03:40