Engineering, 06.05.2020 23:08 coco4937

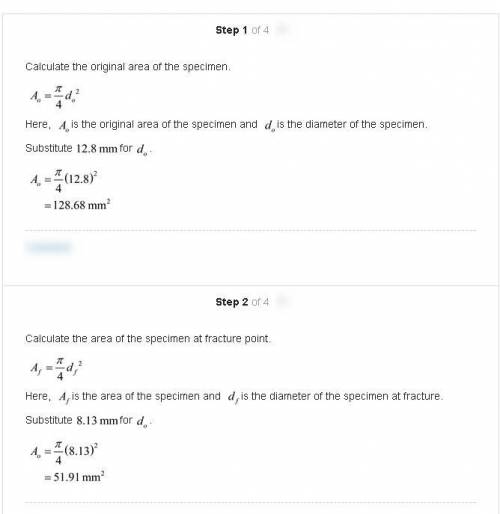

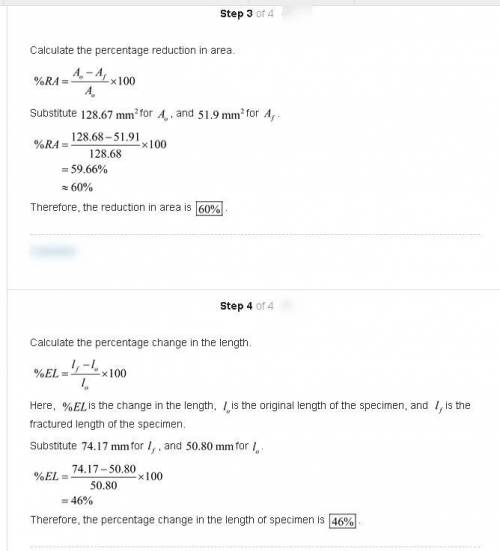

A cylindrical metal specimen having an original diameter of 12.8 mm (0.505 in.) and gauge length of 50.80 mm (2.000 in.) is pulled in tension until fracture occurs. The diameter at the point of fracture is 8.13 mm (0.320 in.), and the fractured gauge length is 74.17 mm (2.920 in.). Calculate the ductility in terms of percent reduction in area and percent elongation.

Answers: 1

Another question on Engineering

Engineering, 04.07.2019 18:10

Coiled springs ought to be very strong and stiff. si3n4 is a strong, stiff material. would you select this material for a spring? explain.

Answers: 2

Engineering, 04.07.2019 18:10

Aplate clutch has a single pair of mating friction surfaces 250-mm od by 175-mm id. the mean value of the coefficient of friction is 0.30, and the actuating force is 4 kn. a) find the maximum pressure and the torque capacity using the uniform-wear model. b) find the maximum pressure and the torque capacity using the uniform-pressure model.

Answers: 3

Engineering, 04.07.2019 18:10

Different types of steels contain different elements that alter the characteristics of the steel. for each of the following elements, explain what the element does when alloyed with steel.

Answers: 2

Engineering, 04.07.2019 18:10

The filament of an incandescent lamp has a temperature of 2000k. calculate the fraction of radiation emitted in the visible light band if the filament is approximated as blackbody

Answers: 2

You know the right answer?

A cylindrical metal specimen having an original diameter of 12.8 mm (0.505 in.) and gauge length of...

Questions

English, 19.09.2020 01:01

English, 19.09.2020 01:01

Computers and Technology, 19.09.2020 01:01

Chemistry, 19.09.2020 01:01

Biology, 19.09.2020 01:01

Mathematics, 19.09.2020 01:01