Engineering, 30.03.2020 19:13 ella8586

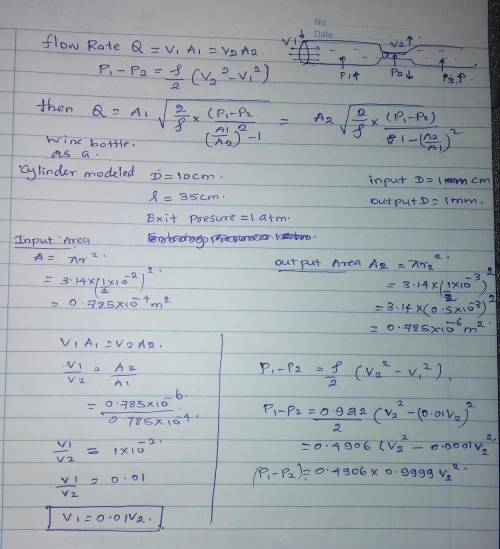

A wine aerator is a small, in-bottle, hand-held pour-through or decantor top device using the venturi effect for aerating the wine. These devices mix air into the wine as it flows through (or over), increasing exposure to oxygen and causing aeration. Apparently, wine which has been aerated tastes better. You want to design a new aerator that will also chill the wine as it is poured. This aerator will be aventuri-shaped tube with an input diameter of 1 cm and an output diameter of 1 mm. Determine the flow rate of the wine exiting theventure tube while pouring as a function of pouring angle and volume of wine in the bottle. The wine bottle can be modeled as a cylinder of 10 cm in diameter and length of 35 cm. You can assume the pressure at the exit is 1 atm and you can assume the head in the bottle while pouring has a pressure of 1 atm. You will need to determine the pressure at the inlet of the aerator as a function of time at various angles. Assume the bottle starts full. Also, calculate the resultant force needed to keep the device attached to the top of your wine bottle as a function of time for the same angles. Comment on maximum forces. Finally, you need to determine the rate that energy needs to be removed to chill the wine from room temperature to 4 C as it flows through the aerator.

Answers: 2

Another question on Engineering

Engineering, 03.07.2019 15:10

If you were designing a bumper for a car, would you prefer it to exhibit elastic or plastic deformation? why? consider the functions of a bumper in both a minor "fender-bender" and a major collision.

Answers: 1

Engineering, 04.07.2019 18:10

Steel is coated with a thin layer of ceramic to protect against corrosion. what do you expect to happen to the coating when the temperature of the steel is increased significantly? explain.

Answers: 1

Engineering, 04.07.2019 18:10

Refrigerant 134a enters an insulated compressor operating at steady state as saturated vapor at -26°c with a volumetric flow rate of 0.18 m3/s. refrigerant exits at 9 bar, 70°c. changes in kinetic and potential energy from inlet to exit can be ignored. determine the volumetric flow rate at the exit, in m3/s, and the compressor power, in kw.

Answers: 1

Engineering, 04.07.2019 18:10

Apipe with an outside diameter of 15 cm is exposed to an ambient air and surrounding temperature of -20°c. the pipe has an outer surface temperature of 65°c and an emissivity of 0.85. if the rate of heat loss from the pipe surface is 0.95 kw per meter of length, the external convective heat transfer coefficient (h) is: (a) 12.5 w/m"k (b) 18.6 w/mk (c) 23.7 w/mk (d) 27.9 w/mk (e) 33.5 w/mk

Answers: 1

You know the right answer?

A wine aerator is a small, in-bottle, hand-held pour-through or decantor top device using the ventur...

Questions

Mathematics, 13.07.2019 12:00

Mathematics, 13.07.2019 12:00

History, 13.07.2019 12:00

Mathematics, 13.07.2019 12:00

Mathematics, 13.07.2019 12:00

Mathematics, 13.07.2019 12:00

History, 13.07.2019 12:00

Mathematics, 13.07.2019 12:00

History, 13.07.2019 12:00

History, 13.07.2019 12:00

Mathematics, 13.07.2019 12:00

Mathematics, 13.07.2019 12:00

English, 13.07.2019 12:00

Geography, 13.07.2019 12:00

Mathematics, 13.07.2019 12:00