Engineering, 09.10.2019 03:30 BigGirlsTheBest

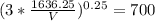

The machine shop has received an order to turn three alloy steel cylinders. starting diameter = 250 mm and length = 625 mm. feed = 0.30 mm/rev, and depth of cut = 2.5 mm. a coated carbide cutting tool will be used whose taylor tool life parameters are n = 0.25 and c = 700, where the units are min for tool life and m/min for cutting speed. compute the cutting speed that will allow the tool life to be just equal to the cutting time for the three parts.

Answers: 3

Another question on Engineering

Engineering, 04.07.2019 18:10

Aplate clutch has a single pair of mating friction surfaces 250-mm od by 175-mm id. the mean value of the coefficient of friction is 0.30, and the actuating force is 4 kn. a) find the maximum pressure and the torque capacity using the uniform-wear model. b) find the maximum pressure and the torque capacity using the uniform-pressure model.

Answers: 3

Engineering, 04.07.2019 18:10

Determine whether or not it is possible to compress air adiabatically from k to 140 kpa and 400 k. what is the entropy change during this process?

Answers: 3

Engineering, 04.07.2019 19:10

Apressure vessel with an r/t 20 cannot be treated as thin walled vessel. a)-trune b)- false

Answers: 3

Engineering, 04.07.2019 19:20

Amass-spring-viscous damper system of mass 3 kg has a frequency of 100 rad/s and is critically damped. its initial conditions are x(0)-3 mm and (0)-2.3 m/s. does the system overshoot its equilibrium position? prove your answer

Answers: 1

You know the right answer?

The machine shop has received an order to turn three alloy steel cylinders. starting diameter = 250...

Questions

Mathematics, 14.11.2020 05:30

Mathematics, 14.11.2020 05:30

Social Studies, 14.11.2020 05:30

Social Studies, 14.11.2020 05:30

Business, 14.11.2020 05:30

Mathematics, 14.11.2020 05:30

Mathematics, 14.11.2020 05:30

Social Studies, 14.11.2020 05:30

English, 14.11.2020 05:30

English, 14.11.2020 05:30

Biology, 14.11.2020 05:30

Chemistry, 14.11.2020 05:30

.......................1

.......................1

× 8.37 = 700

× 8.37 = 700