Case: Kaizen Burst or Bust

Assume that you are a new hire at the company that is buying products from India. This is

a retail apparel company, and you are tasked with getting low costs as well as responsiveness to

the market to meet customer demand. You are part of a Kaizen burst event that is responsible for

looking at the current ordering process. Your task: Identify, suggest, and implement some

improvements. You also need to suggest an idea for the next Kaizen burst event based on what

you do in this event. Team members participating in the Kaizen burst include: Contract manager

(you), Marketing representative, Distribution center associate, Distribution center manager, &

Retail Store associate.

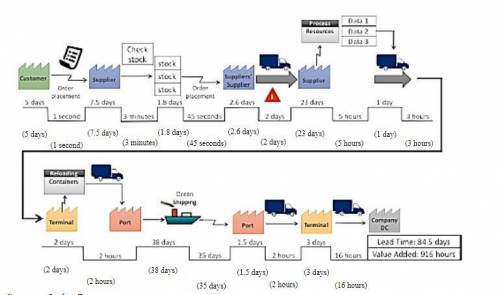

The value-stream map your team has developed is shown below. Your

definition/description of the process follows the map. As your team built the map, you talked about

how Zara is doing all sorts of innovative things to take time out of its supply chain and be more

responsive. You wonder what it would take be more like Zara.

Steps in Order Process

Step 1 –

The customer (that’s us!) review of inventory to determine the actual order placement takes

5 days, with a bit of time spent here and there. This may include some texts/messages sent to the

stores to provide qualitative information on whether they want more of the product, and waiting

for responses. It also includes review of quantitative data related to total sales of that item. Trend, description and seasonal patterns for that item. But there is 1 minute of value-added activity when

the order is actually transmitted.

Step 2 –

On average, from the time that the supplier gets the order until they actually get around to

visually checking the stock takes the supplier 7.5 days, of which time they spend 3 minutes

checking the stock.

Step 3 –

Over the next 1.8 days, the stock information is input into the system and automatically

compared to the customer order, and order is created by the system, with an e-mail sent to the DC

for manual approval. Once that happens, the order is electronically placed with the supplier’s

supplier. The total time in value-added activity is 45 seconds.

Step 4 –

The supplier’s supplier gets the order and fills it and ships the same day if received before

noon. The total time for the order to be picked and shipped until it arrives at the supplier is 2.6

days, including value-added of 10 minutes to process and fill the order, and 2 days of shipping

time. If the supplier does not have the materials in stock, the order is cancelled because it takes too

long to restock the fabrics.

Step 5 –

Once back at the supplier, the order is received, paper work matched, quality checked,

production scheduled and the materials are used in manufacturing. This takes a total of 23 days, of

which 5 hours are value added activity.

Step 6 –

The completed product is loaded on a truck and shipped to a terminal near the port in

Chennai. This takes 1 day, a total of 3 hours value-added.

Step 7 –

The product is loaded into a container which is put on a truck to go to the port and be loaded

on a ship. This takes 2 days, a total of which 2 hours is value- added.

Step 8 –

The ship sets sail around the Cape of Good Hope (Africa), to Miami, FL USA. Where the cargo is

unloaded. This takes 38 days, a total of which 35 days are value added (meaning the boat is

moving). Step 9 –

The container is loaded on a truck to go to a terminal. This takes 1.5 days, a total of which 2 hours

is value-added.

Step 10 –

The container is unloaded at the depot, and put on a truck to go to the customer (our) DC.

This takes 3 days, a total of which 16 hours is value added activity. This includes an average of 2

hours waiting at our DC for the truck to be unloaded.

Total time: 85.4 days (2049.6 hours)

Total value-added time: 38 days, 4 hours, 14 minutes and 45 seconds (or around 916 hours)

Questions:

1. Use the concepts from the eight wastes to identify the areas with the greatest amount of

waste. Identify the type or types of waste in each case.

2. Prioritize the areas that you should focus on in terms of the amount of effort that you would

need to undertake for the amount of potential time savings.

3. Based on what you know, divide up the areas of waste to things that are clearly a part of

your own processes versus the supplier’s process. Which should you tackle first and why?

How much waste do you think you will be able to cut out with your suggestions in each of

the areas that you will tackle?

4. Draw a new “should-be/could be value stream map that incorporates your suggestions.

Answers: 2

Another question on Business

Business, 22.06.2019 01:50

Which value describes the desire to be one’s own boss? a. autonomy b. status c. security d. entrepreneurship

Answers: 2

Business, 22.06.2019 12:30

Suppose you win a small lottery and have the choice of two ways to be paid: you can accept the money in a lump sum or in a series of payments over time. if you pick the lump sum, you get $2,950 today. if you pick payments over time, you get three payments: $1,000 today, $1,000 1 year from today, and $1,000 2 years from today. 1) at an interest rate of 6% per year, the winner would be better off accepting the (lump sum / payments over time), since it has the greater present value. 2) at an interest rate of 9% per year, the winner would be better off accepting the (lump sum / payments over time), since it has the greater present value. 3) years after you win the lottery, a friend in another country calls to ask your advice. by wild coincidence, she has just won another lottery with the same payout schemes. she must make a quick decision about whether to collect her money under the lump sum or the payments over time. what is the best advice to give your friend? a) the lump sum is always better. b) the payments over time are always better. c) it will depend on the interest rate; advise her to get a calculator. d) none of these answers is good advice.

Answers: 2

Business, 22.06.2019 17:30

What do you think: would it be more profitable to own 200 shares of penny’s pickles or 1 share of exxon? why do you think that?

Answers: 1

Business, 22.06.2019 18:00

Biochemical corp. requires $600,000 in financing over the next three years. the firm can borrow the funds for three years at 10.80 percent interest per year. the ceo decides to do a forecast and predicts that if she utilizes short-term financing instead, she will pay 7.50 percent interest in the first year, 12.15 percent interest in the second year, and 8.25 percent interest in the third year. assume interest is paid in full at the end of each year. a)determine the total interest cost under each plan. a) long term fixed rate: b) short term fixed rate: b) which plan is less costly? a) long term fixed rate plan b) short term variable rate plan

Answers: 2

You know the right answer?

Case: Kaizen Burst or Bust

Assume that you are a new hire at the company that is buying products f...

Questions

Mathematics, 27.10.2020 20:00

Health, 27.10.2020 20:00

Mathematics, 27.10.2020 20:00

Mathematics, 27.10.2020 20:00

Spanish, 27.10.2020 20:00

Chemistry, 27.10.2020 20:00

Social Studies, 27.10.2020 20:00

Mathematics, 27.10.2020 20:00

History, 27.10.2020 20:00

History, 27.10.2020 20:00

Mathematics, 27.10.2020 20:00