A steel rolling mill can produce I-beams at the rate of 20 tons per week. Customer demand for the beams is 5 tons per week. To produce the I-beams, the mill must go through a setup that requires changing to the required rolling patterns. Each setup costs the mill $10,000 in labor and lost production. The I-beam cost the mill $2,000 per ton and has an inventory holding rate of 25 percent. Assume the plant operates for 50 weeks in a year. Using Microsoft Excel, calculate the following:

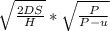

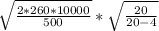

a) the optimal production batch size of the mill.

b) The maximum (highest) inventory level at the plant

c) The annual inventory holding cost

d) The annual setup cost of the plant

e) The annual product cost f) Total Annual Inventory Cost (TAIC)

Answers: 2

Another question on Business

Business, 22.06.2019 06:30

Select all that apply. what do opponents of minimum wage believe are the results of minimum wage? increases personal income results in job shortages causes unemployment raises prices of goods

Answers: 1

Business, 22.06.2019 10:20

What two things do you consider when evaluating the time value of money

Answers: 1

Business, 22.06.2019 18:00

On september 1, 2016, steve loaned brett $2,000 at 12% interest compounded annually. steve is not in the business of lending money. the note stated that principal and interest would be due on august 31, 2018. in 2018, steve received $2,508.80 ($2,000 principal and $508.80 interest). steve uses the cash method of accounting. what amount must steve include in income on his income tax return?

Answers: 1

Business, 22.06.2019 20:00

Later movers do not face: entrenched competitors. reduced uncertainty over technologies. high growth markets. lower market uncertainty.

Answers: 3

You know the right answer?

A steel rolling mill can produce I-beams at the rate of 20 tons per week. Customer demand for the be...

Questions

Mathematics, 08.12.2020 21:10

Mathematics, 08.12.2020 21:10

Mathematics, 08.12.2020 21:10

Mathematics, 08.12.2020 21:10

Social Studies, 08.12.2020 21:10

History, 08.12.2020 21:10

History, 08.12.2020 21:10

Mathematics, 08.12.2020 21:10

Chemistry, 08.12.2020 21:10

Mathematics, 08.12.2020 21:10