Business, 22.04.2020 02:16 buddyben422

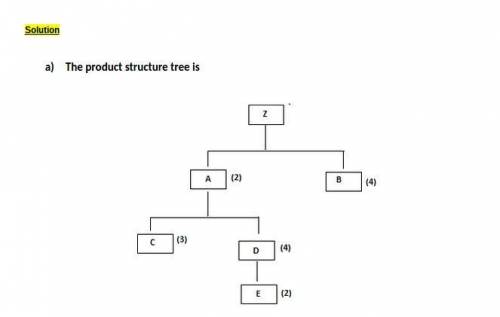

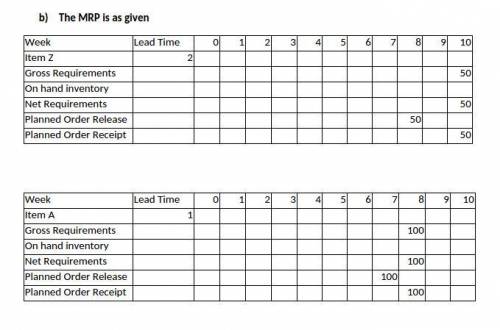

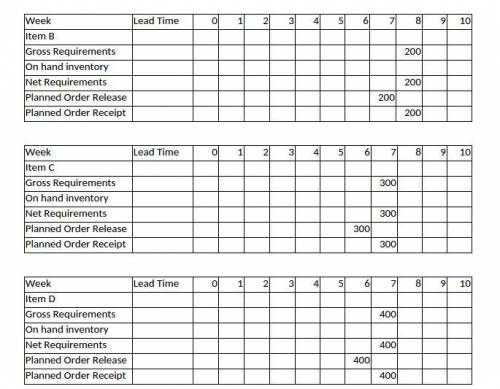

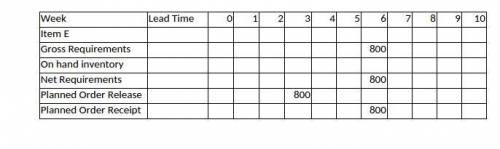

Assume that Product Z is made of two units of A and three units of B. A is made of three units of C and four of D. D is made of two units of E Lead times for purchase or fabrication of each unit to final assembly are: Z takes two weeks; A, B, C, and D take one week each; and E takes three weeks. Sixty eight units of Product Z are required in Period 10. (Assume that there is currently no inventory on hand of any of these items.) b. Develop an MRP planning schedule showing gross and net requirements and order release and order receipt dates.

Answers: 3

Another question on Business

Business, 22.06.2019 05:00

What is a sort of auction for stocks in which traders verbally submit their offers?

Answers: 3

Business, 22.06.2019 05:50

Match the steps for conducting an informational interview with the tasks in each step.

Answers: 1

Business, 22.06.2019 21:20

Which of the following best describes vertical integration? a. produce goods or services previously purchasedb. develop the ability to produce products that complement the original productc. develop the ability to produce the specified good more efficiently than befored. build long term partnerships with a few supplierse. sell products to a supplier or a distributor

Answers: 2

Business, 22.06.2019 22:40

Utilization will always be lower than efficiency because: a. effective capacity is greater than design capacityb. expected output is less than actual output.c. effective capacity equals design capacity.d. effective capacity is less than design capacity.e. expected output is less than rated capacity.

Answers: 3

You know the right answer?

Assume that Product Z is made of two units of A and three units of B. A is made of three units of C...

Questions

History, 07.07.2019 04:00

Biology, 07.07.2019 04:00

Chemistry, 07.07.2019 04:00

Mathematics, 07.07.2019 04:00

Biology, 07.07.2019 04:00

Biology, 07.07.2019 04:00

Geography, 07.07.2019 04:00