Business, 12.02.2020 04:18 jones03riley

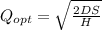

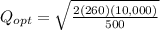

A steel rolling mill can produce I-beams at the rate of 20 tons per week. Customer demand for the beams is 5 tons per week. To produce I-beams, the mill must go through a setup that requires changing to the appropriate rolling patterns. Each setup costs the mill $10,000 in labor and lost production. I-beams cost the mill $2,000 per ton and the mill has an annual holding cost of 25 percent. What is the optimal production batch size for I-beams?

Answers: 1

Another question on Business

Business, 22.06.2019 23:30

What is the difference between career options in the law enforcement pathway and career options in the correction services pathway?

Answers: 1

Business, 22.06.2019 23:40

8. problems and applications q8there are four consumers willing to pay the following amounts for haircuts, and there are four haircutting businesses with the following costs: consumers' willingness to payyvette: $35cho: $15sean: $45bob: $25firms' costsfirm a: $40firm b: $20firm c: $10firm d: $30each firm has the capacity to produce only one haircut.for should be given.which businesses should cut hair? check all that apply.firm afirm bfirm cfirm dwhich consumers should have their hair cut? check all that apply.bobchoseanyvettethe maximum possible total surplus is

Answers: 3

You know the right answer?

A steel rolling mill can produce I-beams at the rate of 20 tons per week. Customer demand for the be...

Questions

English, 24.08.2020 14:01

Biology, 24.08.2020 14:01

English, 24.08.2020 14:01

Mathematics, 24.08.2020 14:01

Mathematics, 24.08.2020 14:01

Mathematics, 24.08.2020 14:01

Physics, 24.08.2020 14:01

World Languages, 24.08.2020 14:01

Mathematics, 24.08.2020 14:01

English, 24.08.2020 14:01

Social Studies, 24.08.2020 14:01

Mathematics, 24.08.2020 14:01