Tco case study distribution example 2015 version 1.2 you work for idc distributions llc.

...

Business, 22.11.2019 06:31 gjvyverman

Tco case study distribution example 2015 version 1.2 you work for idc distributions llc.

you're responsible for sourcing new products. your company is launching a new product. you’ve found two possible sources – a domestic manufacturer and a manufacturer based on south korea. below are more details about each of the manufacturers.

domestic manufacturer

the domestic manufacturer, cornhusker industries (chi), is a qualified supplier. chi will produce a finished good in lincoln nebraska. from there, finished goods will be shipped via rail to your distribution center in dallas. it takes chi 10 days to make an order and then 5 days in transit to your warehouse. shipping costs are fob origin and cost $1,850 per teu (twenty-foot equivalent units). each teu can hold up to 600 units of your product. chi proposed a price of $85.00 per unit when responding to your request for proposal.

global supplier

the other possible supplier is kbm, which is a highly qualified supplier located just outside of seoul korea. kbm ships product via rail to the port of busan, which is located in mouth of the naktong river in south korea. it is the tenth biggest port in the world based on cargo throughput. when an order is placed with kbm it takes 15 days for kbm to manufacture the order and place the order in teus used for shipping. it takes one day for rail from seoul to busan. the shipment will wait 4 days in busan to be loaded on to a ship. from there it takes 16 days to cross the pacific ocean to the port of long beach, and then 3 additional days to clear customs. once the shipment clears customers, it is loaded on to rail and shipped fob origin. it arrives in dallas in 4 days. import tariffs and duties are $325 per teu. rail shipping costs are $2,250 from long beach to dallas. in the rfp, kbm’s bid was 85,477.37 korean won per unit (current exchange rate is $1=1,067 krw).

additional details

transport in the usa, whether from domestic or international suppliers, will travel via rail. the products will be in teus (twenty-foot equivalent units) for shipping and each teu can contain up to 600 units of your new product. your inventory carrying costs are 32.2%. also, each order placed costs $105 for domestic suppliers and $182 for international suppliers. the international ordering costs are higher due to the additional complexity of getting products through customs.

working with your heads of cost accounting and demand planning, you’ve done some preliminary calculations and have determined that: • safety stock required would be 432 units for the global supplier and 160 for the domestic manufacturer • average cycle stock inventory (the average non-safety stock inventory) would be 275.5 for the global supplier and 203.5 for the domestic supplier • annual demand for the new product is 21,500 units • the optimal number of orders (based on demand and eoq formula) for the global supplier is 39.2 and is 52.83 for the domestic supplier • ocean shipping costs from bosan are $1,818 per teu

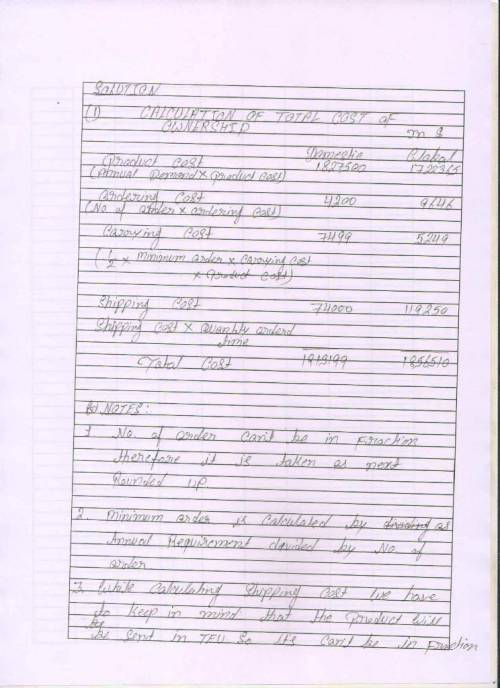

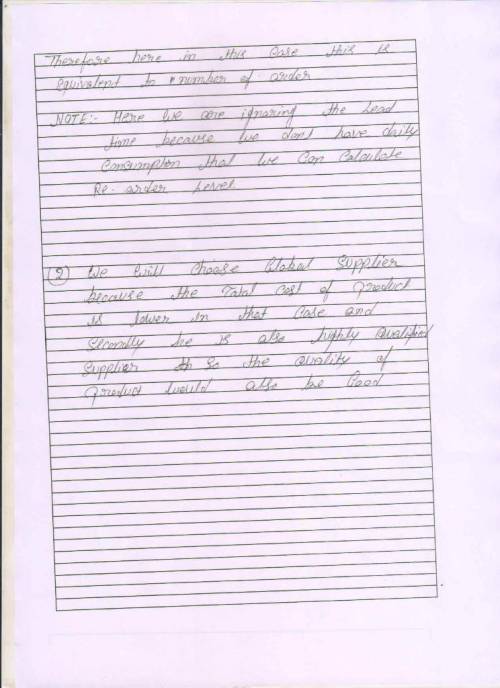

questions: (1) what is the total cost of ownership for each supplier? (2) which supplier would you choose and why?

Answers: 1

Another question on Business

Business, 21.06.2019 22:30

Match the vocabulary word to the correct definition. 1. compensation 2. corporate social responsibility 3. discrimination 4. benefits 5. biodegradable a. a business’s obligation to the community and the environment b. the ability to naturally break down or decompose c. treating someone differently because of his or her race, religion,gender, sexual orientation, or disabilities d. indirect and non-cash compensation paid to employees e. the salary and other benefits for doing a job

Answers: 1

Business, 22.06.2019 03:00

You are the manager of the packaging department in a cookie factory. (obviously, the packaging employees cannot eat the cookies that are transferred in during the period.) after your employees insert cookies into colorful packages (step 1) for display on store shelves, the packages of cookies are then boxed using cardboard cartons (step 2) for shipment to stores. each unit of product is represented by a carton of packaged cookies. the packaging department began the period with 1,000 units of cookies. during the period, 5,000 units of cookies were transferred in from the baking department and 5,500 units of cookies were transferred out to the finished goods department. the number of units of cookies in the ending inventory of the packaging department equals:

Answers: 1

Business, 22.06.2019 08:50

Dyed-denim corporation is seeking to lower the costs of value creation and achieve a low-cost position. as a result, it plans to move its manufacturing plant from the u.s. to thailand, which based on company research, is the optimal location for production. this strategic move will most likely allow the company to realize

Answers: 3

Business, 22.06.2019 09:00

According to this excerpt, a key part of our national security strategy is

Answers: 2

You know the right answer?

Questions

Mathematics, 06.03.2020 09:56

Biology, 06.03.2020 09:56

Computers and Technology, 06.03.2020 09:57

Physics, 06.03.2020 09:57